Leading producers, suppliers, and exporters of top-notch Namkeen Mixing Machines are Omtech Food Engineering. To ensure optimum efficiency and longevity, these machines are created and built utilizing cutting-edge technology and components of the highest caliber.

Namkeen Mixing Machine Manufacturers from Rajkot

The Omtech Food Engineering Namkeen Mixing Machine is used to evenly combine a range of namkeen and snack components. The machine features a strong structure that can endure heavy-duty activities and a strong motor.

The Namkeen Mixing Machine is offered in a range of sizes and capacities to satisfy the varying needs of customers. Additionally, Omtech Food Engineering provides tailored solutions to satisfy particular client requirements.

The Namkeen Mixing Machine is a cost-effective option for snack producers since it is simple to use and needs little maintenance. The equipment is also sanitary and simple to clean, assuring the finished product’s safety and quality.

The team at Omtech Food Engineering is made up of highly qualified individuals who are committed to providing customers all around the world with Namkeen Mixing Machines of the highest caliber. To ensure that customers get the most out of their investment, the firm also provides exceptional after-sales assistance, including installation, training, and maintenance services.

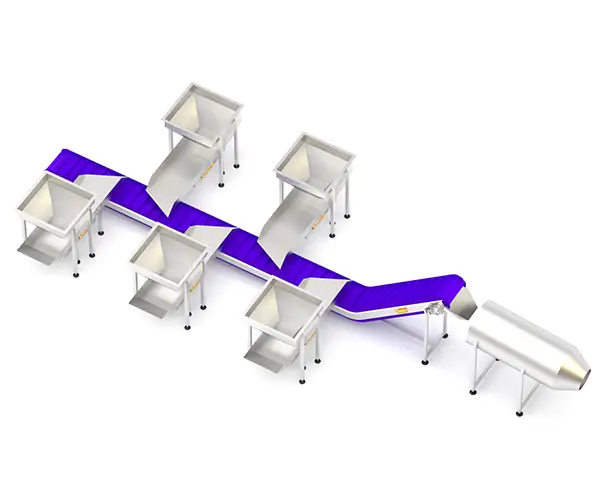

Conveyor System in Namkeen Industry | Omtech Food Engineering

With range of our expertise, we can fabricate fryer infeed conveyor systems for Namkeen industry. The hygienic design of our conveyors allows sanitation with belts that are easy to clean and quick. Our Conveyor System offerings for the namkeen industry feature an automated washing system that reduces time and labor. Conveyor system in the namkeen industry offered by us provides proven as well as reliable low-cost operations experience in under-regulated and controlled production or process line environments. With these conveyors based on proven design and operational technology standards, it can deliver optimum material conveying environment in the namkeen industry that is not only reliable but also delivers low maintenance operation, thus suiting changing needs of the business.

The use of food-grade mild steel or stainless steel also ensures these are safe to use in a regulated and sanitized dairy environment. Some advantages these systems deliver include relatively low operational expense, quality conveyor equipment, and proven and reliable performance.