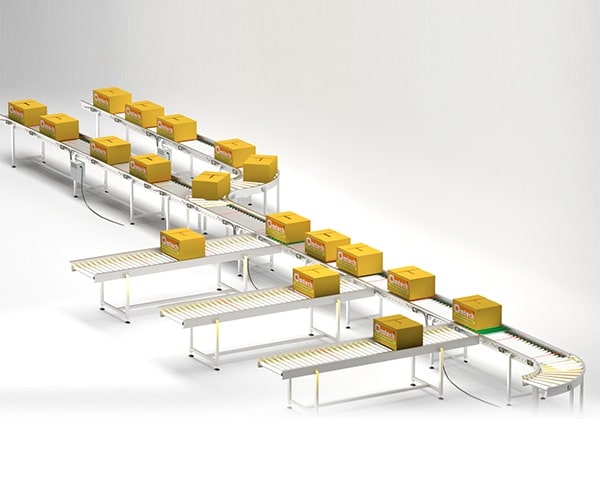

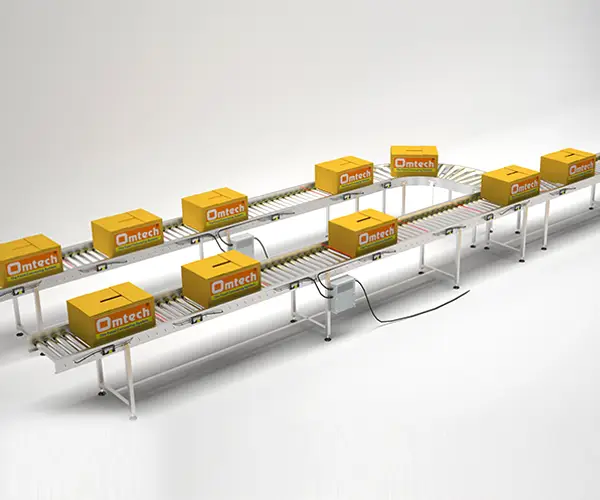

Zero Pressure Accumulation Roller Conveyor System Manufacture

Omtech Food Engineering is a leading manufacturer, supplier, and exporter of Zero Pressure Accumulation Roller Conveyor Systems. These systems are designed to provide high-quality material handling solutions for various industries, including food and beverage, pharmaceuticals, automotive, and more.

The Zero Pressure Accumulation Roller Conveyor System is designed to transport items without any pressure or contact between them. This is achieved by using sensors and controls that detect the presence of items on the conveyor and adjust the speed of the rollers to ensure smooth and gentle movement. This helps prevent damage to delicate or fragile items and ensures that they are transported safely and efficiently.

At Omtech Food Engineering, we offer a range of Zero Pressure Accumulation Roller Conveyor Systems that can be customized to meet the specific needs of our clients. These systems are designed to handle a wide range of items, from small electronic components to large automotive parts. They can be used for a variety of applications, including assembly, packaging, sorting, and distribution.

Our Zero Pressure Accumulation Roller Conveyor Systems are made from high-quality materials, such as stainless steel, and are built to last. They are easy to install and maintain, and come with a range of features and options, including adjustable speed controls, variable frequency drives, and more.

At Omtech Food Engineering, we are committed to providing our clients with the best possible material handling solutions. Our team of experts works closely with our clients to understand their specific needs and develop customized solutions that meet their unique requirements. Whether you need a single conveyor or a complete material handling system, we have the experience, expertise, and resources to deliver the right solution for your business.